Contact Info

Resources

Uni Hitemp 305

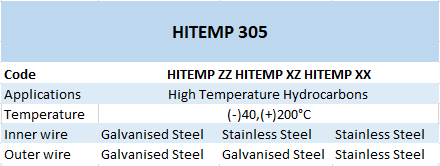

Construction

Universeflex Hitemp 305 is a multi-layer thermoplastic hose designed around several Fluoropolymer liners, supported by a Stainless Steel inner wire, and reinforced with films and fabrics specifically designed for high temperature applications. All the different layers are wrapped together and tensioned between internal and external wire spirals.

Universeflex Hitemp 305 utilizes the new PTFE laminate film Nanotec, obtained with the latest and highest standard of Nanotechnology, ensuring unique mechanical strength and zero porosity, Nanotec technology is a Patented Design exclusive and unique, belonging to Matec Group. Includes in the construction an FEP seamless tubular extruded film, to avoid any possible leak and guarantee a gas-tight construction, (PATENT N°IT0281052) Outer cover is made in Elastothane, a special High temperature resistant PU coated fabric; its UV, Ozone, Sunlight and weathering resistance, offers as well superior abrasion resistance characteristics.

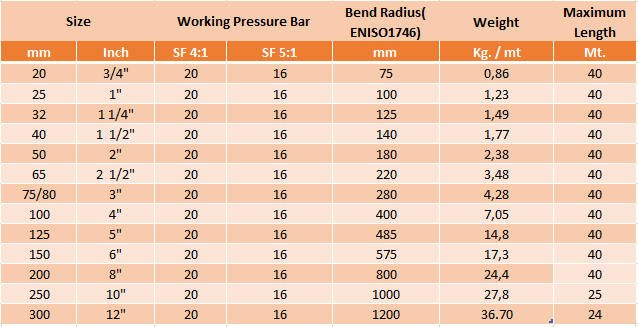

Available in 40 mt coils from 3/4” to 4” and 25 mt length up to 12”.

Applications:

Universeflex Hitemp 305 is specifically designed as an hose for the transfer of HOT OIL and bitumen under positive or negative pressures, Hitemp 305 hose are used in such applications as transfer for rail and road tanker loading and unloading, storage tank and in-plant use. Extremely flexible, easy to handle and bend, even at very high or very low outdoor temperatures. All hoses are 100% aromatic resistant, antistatic and can be used for suction or discharge. Vacuum rating is 0,9 bar, according to the EN ISO 7233 method B. Thanks to the inner PTFE Nanotec construction, nothing sticks to the inner wall of the hose, and due to absence of inner corrugations or convolutions, (smooth body), nothing will remain trapped in it.

Universeflex Hitemp 305 hoses are supplied in the Firetec version to meet the Fire retardand performance criteria acc. to European Standards EN 13765:2010 Normative, Annex G, and with ADR self-estinguish CL1 characteristics.

The special series of Hitemp 305 Firetec hoses, are mainly used for cooling application in the Steel industry. On specific request, it is possible to supply hoses electrically discontinuous (non conductive), in particular for the Induction ovens in Steel plants. Additional fire resistant films and fabrics are included in the construction to ensure a good thermal insulation and a low conductivity from the outside to the inside. The special series of Coated Firetec hoses, have additional external heat resistant layers, to withstand the action of eventual splashes of fused metals.

The coating can be made in various materials:

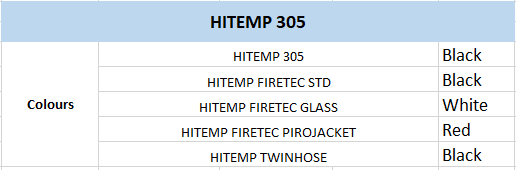

Hitemp Firetec Std: Black colour self estinguish CL 1 coating. Additional underlayers of glass fabrics and Aluminium films to act as a heat and fire barrier.

Hitemp Firetec Glass: Outer cover made with Glass cloth type E , with good thermal characteristics and fire resistance properties.

Hitemp Firetec Pirojacket: Special outer cover made with red silicone impregnated silica fabric, combines handling properties and extreme temperature resistance.

Universeflex Hitemp 305 Twinhose it’s a special type of hose designed for the transfer of Highly viscous products, at temperatures that can reach 200° C. To improve the durability, reliability, and ensure absolute absence of leaks, we included a coaxial interlock liner, made in steel with a smooth bore structure, in order to avoid any stagnation of the product once the loading / unloading operations are finished, and to avoid any wire diplacement due to the high viscosity of the products flowing in the hose.

Universeflex Hitemp 305 assemblies are fitted with an extensive range of couplings also available PTFE tafted or with the new exclusive Eptaflon treatment, externally swaged with Stainless Steel ferrules. Upon request it is possible to supply electrical insulating fittings, with the Ebonite coating.

A 3 mt x 6” assembly of Universfelex Firetec hose, filled with liquid F of ISO 1817, has been independently tested in an outdoor application, and subjected to direct naked flame. After the test, the hose has maintained its structure intact, with no significant alteration.

Universeflex assemblies are tested in accordance with EN ISO 1402. The securing ferrule is permanently engraved, with hose datas, in compliance with PED Directive (97/23/ CE). Upon request it’s possibile to manufacture COMPOTEC® hoses in accordance to the Directive 94/9/EC “Atex”, with a special outer antistatic black cover, ground connection cable, for explosive environment.

All Universeflex meets the EN, CE, AS, U.S. Coast Guard requirements, NAHAD Guidelines, are Lloyd’s and DNV approved.