Contact Info

Resources

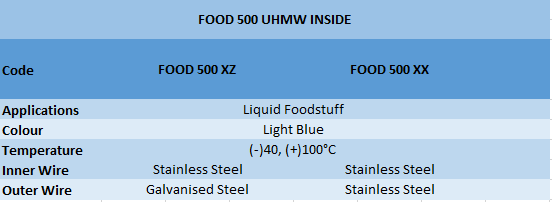

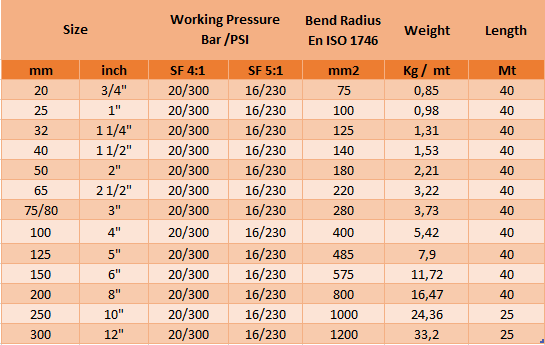

Uni Food 500

Universeflex Food 500 is a multi-layer thermoplastic hose designed around several Ultra High Molecular Weight Polyethylene (UHMW PLT) liners, supported by 316 L Stainless Steel inner and outer wires, with a weather-proof and abrasion resistant outer cover made of Polyvinyl coated Polyester fabric. Outer cover is also available in Elastothane, a special PU coated fabric with extra UV, Ozone, Sunlight and weathering resistance, offering superior temperature and abrasion characteristics.

Extremely flexible, easy to handle and bend, Food 500 hose complies with International regulations, for all the application in direct contact with food. During all the phases of production, the hose is controlled in an high purity process of manufacture. No oils or lubrificants are used during the process to avoid any possible contamination.

With its Heavy Duty construction, includes in the construction an High Density PLT seamless tubular extruded film, to avoid any possible leak and guarantee a gas-tight construction. All the different layers are wrapped together and tensioned between internal and external wire spirals.

It is possible to clean Food 500 with loose steam or with various chemicals (diluted caustic soda and nitric) without any problem. All hoses are 100% antistatic and can be used for suction or discharge. Vacuum rating is 0,9 bar, according to the EN ISO 7233 method B.

Universeflex Food 500 assemblies are fitted with an extensive range of couplings readily available, including Sanitary type fittings, DIN, SMS, RYT or Tri-Clamp, externally swaged with Stainless Steel ferrules.

Universeflex Food 500 Specifically designed as a universal hose for the transfer of a wide variety of liquid or food products in general, under suction or pressure, Food 500 hoses are used in such applications as transfer for rail and road tankers, loading and unloading, storage tank and in-plant use. Particularly recommended in all the edible oils transfer, including Palm, Coconut, Sunflower, seeds or olive oils. It is widely used as well for chocolate, jam, edible or pure alcohol, isopropyl, ethyl, methyl or alcoholic spirits, wine and liquors.

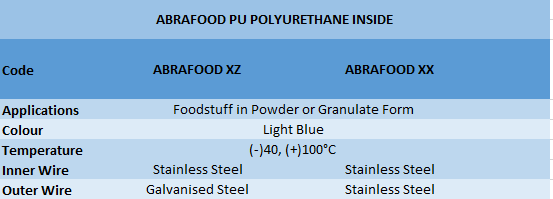

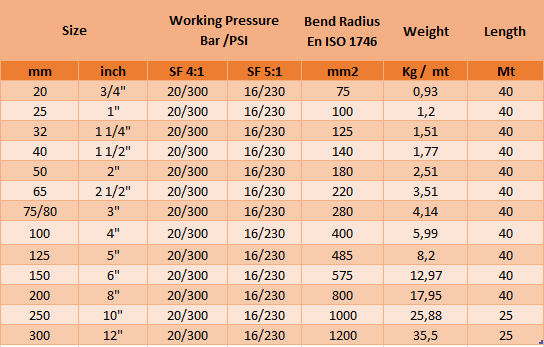

Universeflex Abrafood Pu

Universeflex Abrafood Pu has been designed for the transfer of all abrasive Foodstuffs, liquids, powders or granulates. Thanks to the high thickness of its Food Grade Polyurethane layers, and the Heavy Duty construction, it is succesfully used for the transfer of sugar, cereals , flours, and in general all abrasive alimentary products. Universeflex Abrafood Pu includes in the construction an High Density PLT seamless tubular extruded film, to avoid any possible leak and guarantee a gas-tight construction. All the different layers are wrapped together and tensioned between internal and external wire spirals. 100% Antistatic construction.

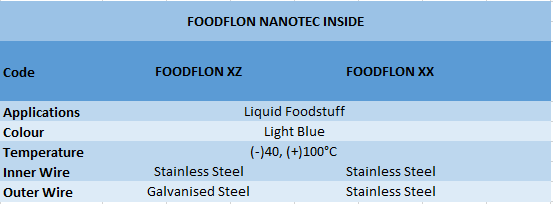

Universeflex Foodflon

Universeflex Foodflon It’s been engineered and designed for all the application where Food compatibility needs to be combined with Chemical resistance, Teflon inertness, and where higher temperatures are involved. Foodflon hose uses as a first layer the new patended Nanotec PTFE film, having an incredible 360° tear strength, superb durability and operating temperatures of up to 316°C/600°F.

Universeflex Foodflon can be easily cleaned with any type of chemical product and with pressurized Steam.

Universeflex Food 500 assemblies are tested at 1 ½ times rated working pressures for safety and reliability, in accordance with EN ISO 1402. The ferrule, is permanently embossed, with manufacturer’s name, nominal bore, the serial number and the last test date of the hose assembly . Full test certification can be supplied on request.

Electrical continuity is achieved by the two wires bonded to the end fittings, this helps dissipate accumulated charge and to avoid static flash. Upon request it’s possibile to manufacture Food 500 hoses in accordance to the Directive 94/9/EC “Atex”, with a special outer antistatic cover.