Contact Info

Resources

Uni Oil 800

Universeflex Oil is a multi-layer thermoplastic hose manufactured from Polypropylene, Polyethylene and Polyester films and Polypropylene fabrics, with a weatherproof and abrasion resistant outer cover made of Polyvinyl coated Polyester fabric. Outer cover is also available in Elastothane, a special PU coated fabric; its UV, Ozone, Sunlight and weathering resistance, offers superior temperature and abrasion characteristics.

All the different layers are wrapped together and tensioned between internal and external wire spirals. This enables our product to meet the requirement of the Petrol -chemical industry and those of the Oil & Gas industry.

Universeflex Oil assemblies are fitted with an extensive range of couplings readily available, externally swaged with crimping ferrules.

Universeflex Oil assemblies are tested at 1 1⁄2 times rated working pressures for safety and reliability, in accordance with EN ISO 1402. The securing ferrule, at one end of the hose, is permanently marked by engraving, with manufacturer’s name, nominal bore, the hose assembly serial number and the test date. The marking of hose assemblies is made in compliance with PED Directive (97/23/ CE). Full test certification can be supplied on request.

Universeflex Oil hoses can be supplied in the Firetec version with ADR selfestinguish CL1 cover and additional fireproof layers.

Burst pressure indicated, is at ambient temperature when tested in accordance with EN ISO 1402.

Electrical continuity is achieved by the two wires bonded to the end fittings, this helps dissipate accumulated charge and to avoid static flash. Upon request it’s possibile to manufacture Universeflex hoses in accordance to the Directive 94/9/ EC “Atex”, with a special outer antistatic black cover, ground connection cable, for explosive environment.

Universeflex Oil 800 HD and OIL SD hoses are specially engineered for the transfer of hydrocarbons, including oil, petrol, diesel, lubricating oils, MTBE, paraffin and 100% aromatics, in all kinds of transfer. The range includes:

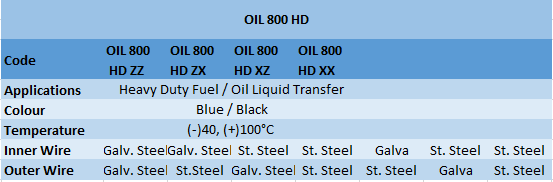

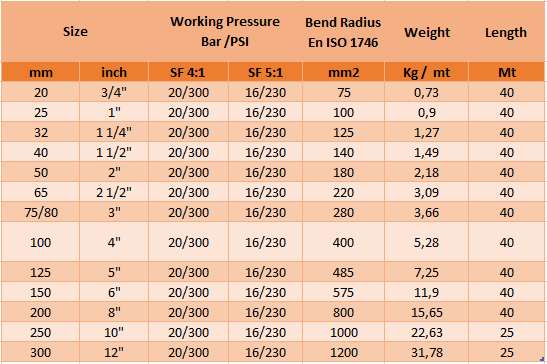

Oil 800 HD – Heavy Duty

Applications:

Heavy Duty construction for the transfer of a wide variety of hydrocarbon conveyant under suction or pressure. Used for black oils and heavier lubricating products, Ship to Shore and Ship to Ship, Dockside and in general for the most ardous Industrial and Marine applications. Commonly used for all hose loading arms in Bottom Loading operations, thanks to the special reinforcement for minimal elongation. Fully suitable for 100% aromatics & MTBE transfer.

Construction:

High strength polypropylene and polyester films and fabrics, high density polyethylene films reinforcement, includes in the construction an High Density UHMW PLT seamless tubular extruded film, to avoid any possible leak and guarantee a gas-tight construction, Polyvinyl coated polyester fabric cover, (or ELASTOTHANE® upon request) weather and ozone resistant. Available in 40 mt coils from 3/4” to 8” and 25 mt length up to 12”.

Universeflex Oil 800 HD hose assemblies are certified by D N V as complying the requirements of CE Directive 97/23 “Ped” and are manufactured in accordance with the requirements of Paragraphs 2:12 and 5:7 of the IMO Chemical Carrier Code. Universeflex Oil 800 HD hoses are Type approved by Lloyd’s with Certificate n° 13/0002.

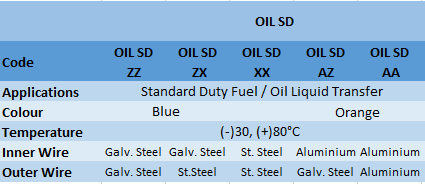

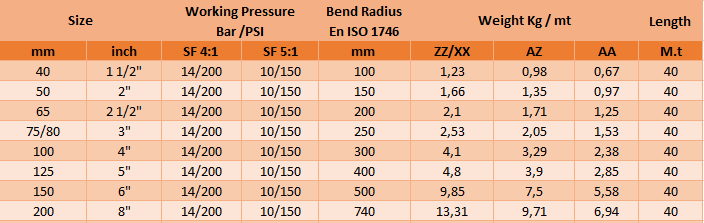

Oil SD – Standard Duty

Applications :

General purpose Standard Duty hose suitable for the safe transfer of a wide variety of hydrocarbons, including fuel oils, petrol, diesel, lubricating oils, kerosene, MTBE, and 100% aromatics under suction or pressure. Commonly used for road and rail tanker loading and discharging, storage tank and in-plant use. Suitable as flexible hose for Top Loading arms.

Available in 40 mt coils from 1 1/2” up to 8”.

Construction:

High strength polypropylene films and fabrics, high density polyethylene film reinforcements, Polivinyl coated polyester fabric cover, weather and ozone resistant.

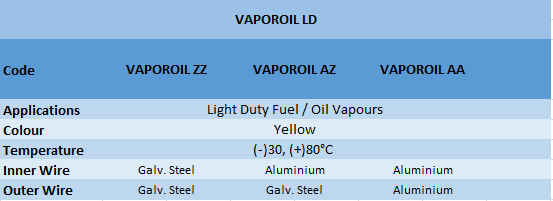

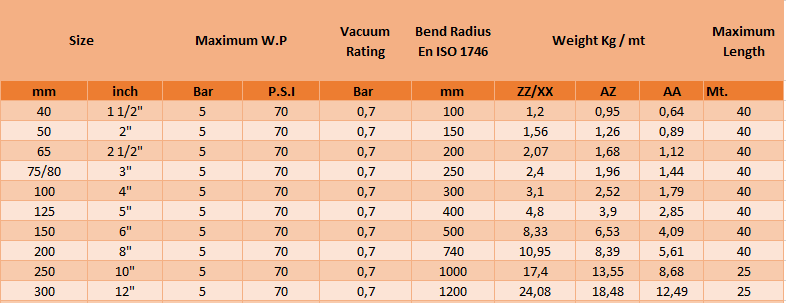

Vaporoil Light Duty

Applications:

General purpose Light Duty hose is ideal for use in petroleum and petrochemical vapor recovery systems in ship to shore, ship to ship, bottom loading and tank truck operations. Complies with USCG Marine Vapour control system 33CFR Part 154.810.

All Universeflex hoses are 100% Antistatic – Electrically continuous, meets the EN, CE, AS, U.S. Coast Guard requirements, NAHAD Guidelines, are Lloyds and DNV approved and Atex certificate can be released on request